Intermountain West

As anyone in the construction industry (or anyone who has ever been involved in a construction project, for that matter) knows, new and remodeled buildings must adhere to a strict set of codes. Like them or not, building codes were put in place for safety purposes, and contractors are required to follow them to the letter. So, if the approved plans say that rebar must be placed a specific distance apart in a concrete masonry unit (CMU) wall, that’s what must be done.

However, sometimes, unscrupulous contractors decide to ignore code requirements and take shortcuts to get the job done cheaper (and put more money in their own pockets). That’s the scenario we encountered at a Veterans Administration hospital project. Our team was brought in for our rebar scanning expertise to check whether the building’s rebar had been installed according to code.

Why Rebar Scanning Is Sometimes Needed

Let’s start from the beginning and talk about what rebar is, why it’s necessary in certain buildings, and when rebar scanning would be required.

Rebar is a metal reinforcing rod, typically made of steel, that is placed in concrete to help increase its tensile strength. Buildings that have concrete foundations and walls are structurally reinforced with rebar, and the size, grade, and placement of these bars are all critical components of any construction plan. Typically, contractors who install the rebar are required to have their work inspected prior to pouring the concrete to ensure it meets the engineer’s plan, as well as all relevant code requirements.

Occasionally, contractors fail to call for the necessary rebar inspection, and other components, like concrete and roofing, are installed over the rebar, hiding it from visual inspection. When that happens, the project can require ground penetrating radar (GPR) scanning to verify that the rebar was installed properly and according to the approved plans.

While all projects have specific requirements to ensure the structural integrity of the building, government projects like this one have even more stringent requirements. There is almost no wiggle room when it comes to meeting their specifications.

Why Rebar Scanning Was Needed for This Project

The government-approved plans for this VA hospital mandated that the rebar in the CMU walls be spaced out at specific intervals to increase the walls’ strength. It is the mason’s job to place the rebar at the specified intervals, pour the concrete, and ensure that the rebar stays spaced correctly throughout the process. Best practice is to use specially designed rebar spacers to keep the rebar in position as the concrete is poured and set.

Whether to save money on spacers or to expedite the job, the mason elected not to use rebar spacers. Instead, the workers were instructed to move the bars apart as they were pouring the concrete to make sure the rebar wasn’t touching. This inexact process meant that some bars may have ended up too close together, while others weren’t close enough.

Because the mason didn’t call for concrete inspection before the roof was added, there was no way to visually determine if the work met the engineer’s specs or not. Government inspectors told the contractors that they may need to tear the building down and start over to ensure the rebar was installed properly. That’s when our team was called in for rebar scanning.

Rebar Verification Using GPS Scanning

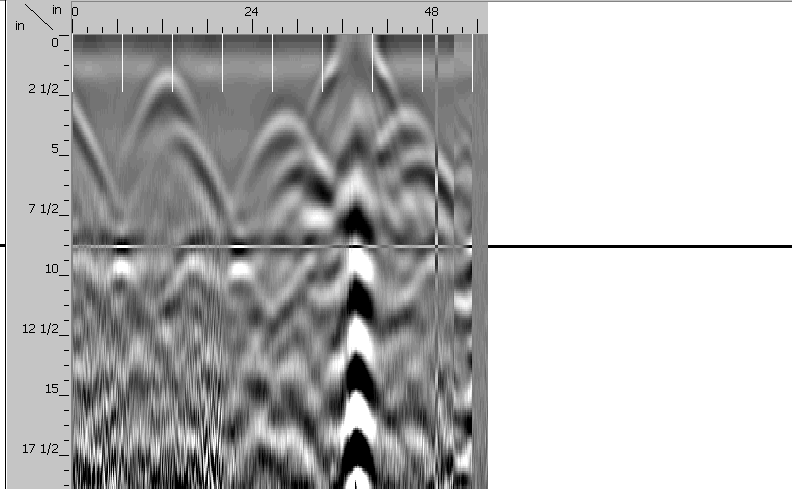

In an effort to avoid a costly rebuild, Enhanced Scanning was brought in to use our GPR equipment to scan the walls and determine if the rebar had been properly spaced. To get the most accurate data possible, we had to use our GPR’s dielectric constant estimates and our own groundtruthing skills to determine the exact depth of a CMU block.

In most cases, the dielectric constant of concrete is about six, on a scale of one to 81. This number tells us how well an electromagnetic pulse (EMP) will move through a substance and is necessary for precise GPR location. But since our equipment only provides estimates for the dielectric constant, we also have to use direct observation to calibrate the GPR antenna to the exact CMU depth. Known as “groundtruthing,” this skill is vital for ensuring maximum accuracy.

Once we determined the scanning depth, we proceeded to scan the walls while standing on an A-frame ladder. Typically, we use a scissor lift for this process for safety and efficiency, but a scissor lift wouldn’t fit in our working space. So, we had to climb up on the ladder, scan as far as we could reach, step down one rung, move the GPR antenna, and repeat. It wasn’t ideal, but we made it work.

Under normal rebar verification circumstances, building owners typically want two or three small sample areas scanned so an overall rebar pattern can be established. This was no ordinary job, however. To avoid the worst-case scenario of having to tear down the building and start over, we scanned numerous large areas of the structure to gather sufficient data to satisfy the inspector. Following the meticulous GPR scanning work, we provided a comprehensive report detailing the results.

Delivering the Rebar Scanning Results

The results of our scan showed that the rebar was not properly spaced in the walls. In fact, the rebar was nearly touching in some places, which confirmed the inspector’s concerns. The only other way the project managers could have found this out would have been by tearing the building down.

It was our job to provide the most thorough, detailed information possible to help the inspectors make decisions about the building. While we suspect the two sides were able to come to a resolution that didn’t involve tearing down the entire building, we don’t really know the final outcome.

What we do know is that we were able to pinpoint the rebar in the walls without disturbing the concrete, saving everyone involved time and money. When you look at it from that perspective, the job was a success. It was the most in-depth rebar verification project we’ve ever been involved with, and its success highlights our diligence and GPR expertise.

Whether a project is government regulated or not, Enhanced Scanning provides thorough and accurate results for rebar verification and other GPR scanning services. Contact us today for GPR scanning and get the critical information you need to make the best decisions for your property.