Intermountain West

Post-tension slab drilling, cutting, and coring are all potentially dangerous activities. Not only is there a risk of structural collapse, but there is also a very real danger of severe injury or death to anyone nearby. It is definitely not something you want to play around with.

So, what do you do when you need to drill into post-tension concrete (also called PT concrete)? If you’re smart, you call in experts to thoroughly scan your concrete slabs to accurately locate all post-tension cables.

That’s exactly what this client did.

Changes to a Building Site Require Post-Tension Concrete Drilling

Before the 2008-2009 recession, our customer’s company bought three lots on the same road. The plan was to build three sets of condos. They built one set of condos on the center lot, with a parking garage underneath, but just as they finished pouring slabs on the parking garage on the two remaining lots, the recession hit. They decided to put tar paper and sod over the parking garages and turned them into parks. They left them like this for more than five years.

When the time came to resume building, the company decided to build condos on one of the two lots, but wanted to make drastic changes to the condo complex’s design. Unfortunately, the concrete had already been sleeved according to the original design, and the company wanted to move everything. Since they were dealing with post-tensioned concrete, this presented a big challenge.

Now, post-tensioned cables are great because they allow concrete slabs to be more stable, while also being thinner. The downside is, if you need to cut into the concrete down the road, and you accidentally hit a cable, the cable can snap, much like a rubber band.

When you’re engaging in post-tension slab drilling, cutting, or coring, you want to avoid this snap at all costs. A snapped cable has the potential to cause serious injury or even death. Ideally, you wouldn’t ever cut into a post-tension slab after the concrete is formed, but sometimes plans change.

Our customer needed to core in 130 separate spots through their PT concrete, so he called us.

GPR Scanning Prior to Post-Tension Slab Drilling

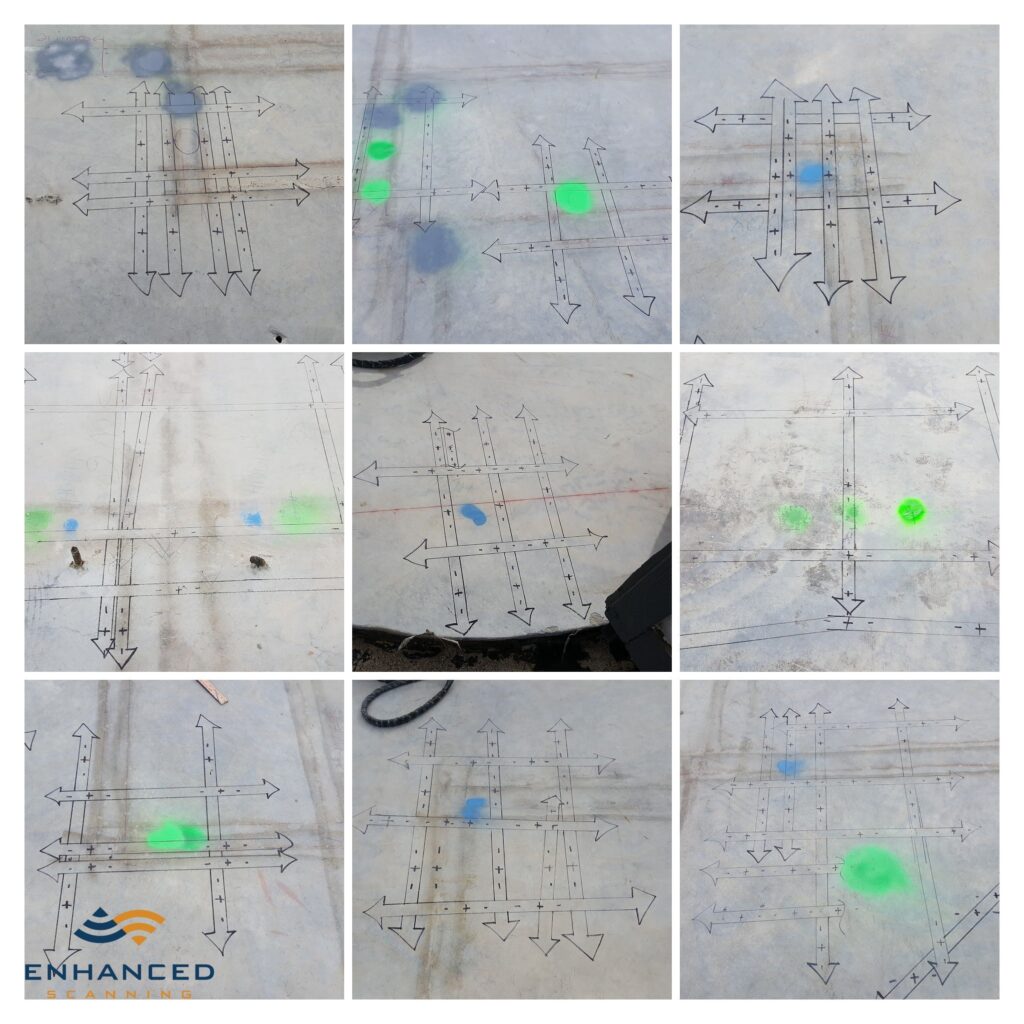

Using our 1.6 GHz ground penetrating radar (GPR) antenna, we scanned every proposed coring location in the post-tension slab, taking the time to make sure it was safe to drill in each spot. In some cases, they were cleared to drill right where they wanted, but more often than not, they had chosen a spot right where a PT cable was sitting.

When we came across a section with a PT cable underneath, we indicated the spot with marks on the concrete and then proposed an alternative spot nearby where they could core. The exchange between our team and the customer sounded something like this: “There’s PT cable here, here, and here, but if we move the core eight inches to the left, you’re in the clear to drill.”

How the Post-Tension Slab Coring Turned Out

Of course, when the time came to actually do the post-tension slab coring, everyone was (understandably) a little nervous. As stated earlier, hitting a PT cable could have disastrous consequences. Fortunately, there was no need to worry. In the end, not one single cable was cut—or even nicked—despite drilling in 130 different locations throughout the slab.

That’s right! No hits. Zero near misses. It was a 100% perfect job on the part of the Enhanced Scanning team! Our customer was extremely happy with our attention to detail because it meant his project could move forward safely and with no delays.

At Enhanced Scanning, we pay attention to the smallest details to help ensure the safety of your workers and a successful outcome to your project. Our team is thorough, disciplined, and focused on every single job we do.

Even if your job is the last one we complete on a Friday afternoon, we never compromise our professionalism or attention to detail. Contact us today for GPS scanning prior to cutting, coring, or drilling into your post-tension slab (or any other type of slab).